Milling

Our product range includes single-blade, multi-blade, milling plates, milling cutters, gravers, milling heads, drills, high-gloss milling cutters and shell-type milling cutters of all types for the special use of ultra-hard cutting materials such as CBN (cubic boron nitride), PCD (polycrystalline diamond), CVD diamond (CVD thick film diamond), MCD (monocrystalline diamond) and natural diamond.

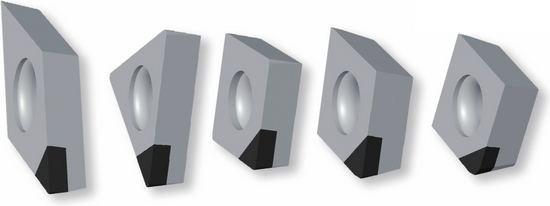

ISO milling plates with diamond cutting edges

- Diamond blanks brazed or vacuum-brazed onto standard carbide inserts

- Depending on the cutting material, the diamonds contain soft binders (PCD) or none (CVD diamond, MCD and natural diamond)

- Choice of diamond type according to application

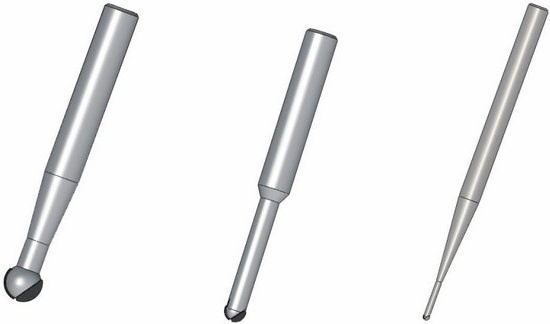

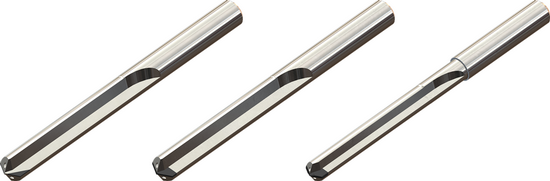

Finger and radius cutters with diamond cutting edges

- Diamond inserts brazed to carbide blanks

- Depending on the cutting material, the diamonds contain soft binders (PCD) or none (CVD diamond, MCD and natural diamond)

- Choice of diamond type according to application

Ball cutters with PCD cutting edges

- PCD blanks brazed to carbide blank

- Use of special PCD type

- Cutting wires eroded

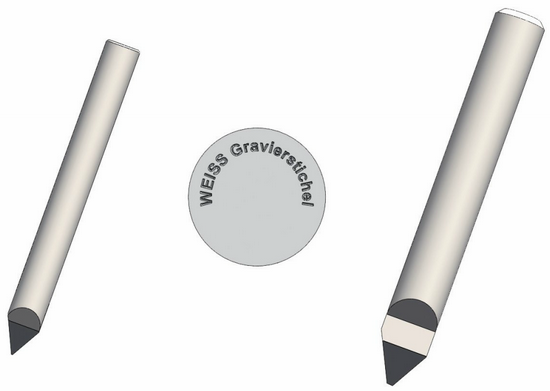

Diamond gravers

- PCD version brazed to carbide blanks

- Use of a fine PCD variety

- single cutting edge

- conical bevel

- regrindable

WEISS multi-tooth cutters with PCD cutting edges

- PCD inserts brazed to carbide blank

- Use of a special PCD variety (A56)

- Cutting wires eroded

PCD shell-type milling cutters

- PCD blanks brazed on carrier

- Regrindable or reerodible

- Large number of teeth

- Use in roughing and finishing operations

- Cooling possible on all cutting edges

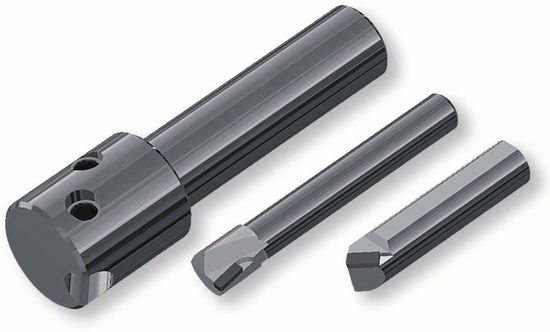

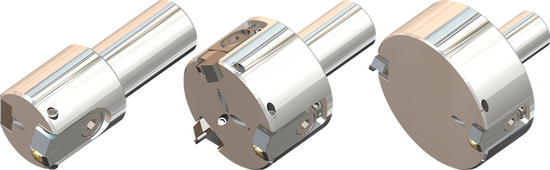

Finger milling cutter (CBN), milling head inserts and milling heads

- Tool holders for diamond or CBN-tipped inserts

- Inserts brazed or vacuum brazed onto steel beams

Finger and radius cutters with lasered CVD or PCD cutting edges

- Diamond inserts brazed or vacuum-brazed

- Internal cooling

- Carbide shank with h5 tolerance

- PCD grade A041 (wear resistant PCD grade)

Areas of application

Tools with diamond cutting edges achieve excellent results with regard to tool life, surface quality and production times and are therefore especially suitable for large quantities or high levels of tool wear.

The high abrasion resistance results in very long tool life and thus low downtimes of production machines.

CVD diamond drills with lasered cutting edges

- Vacuum-brazed CVD diamond inserts

- Internal cooling

- Lasered diamond cutting edges

- Carbide shank h5 tolerance

- CVD diamond with polished face

Areas of application

Tools with diamond cutting edges achieve excellent results with regard to tool life, surface quality and production times and are therefore especially suitable for large quantities or high levels of tool wear.

The high abrasion resistance results in very long tool life and thus low downtimes of production machines.

High-gloss milling cutters with MCD or natural diamond cutting edges

- MCD or natural diamond in cutting cassettes

- Regrindable

- Individually adjustable teeth

Areas of application

These tools are used to achieve very high surface qualities.

Main areas of application

- Plexiglas

- Aluminium

- Brass

Speed range: 1500 - 8000 rpm (depending on machine and material)

Feed range: 0.02 - 0.05 mm / R