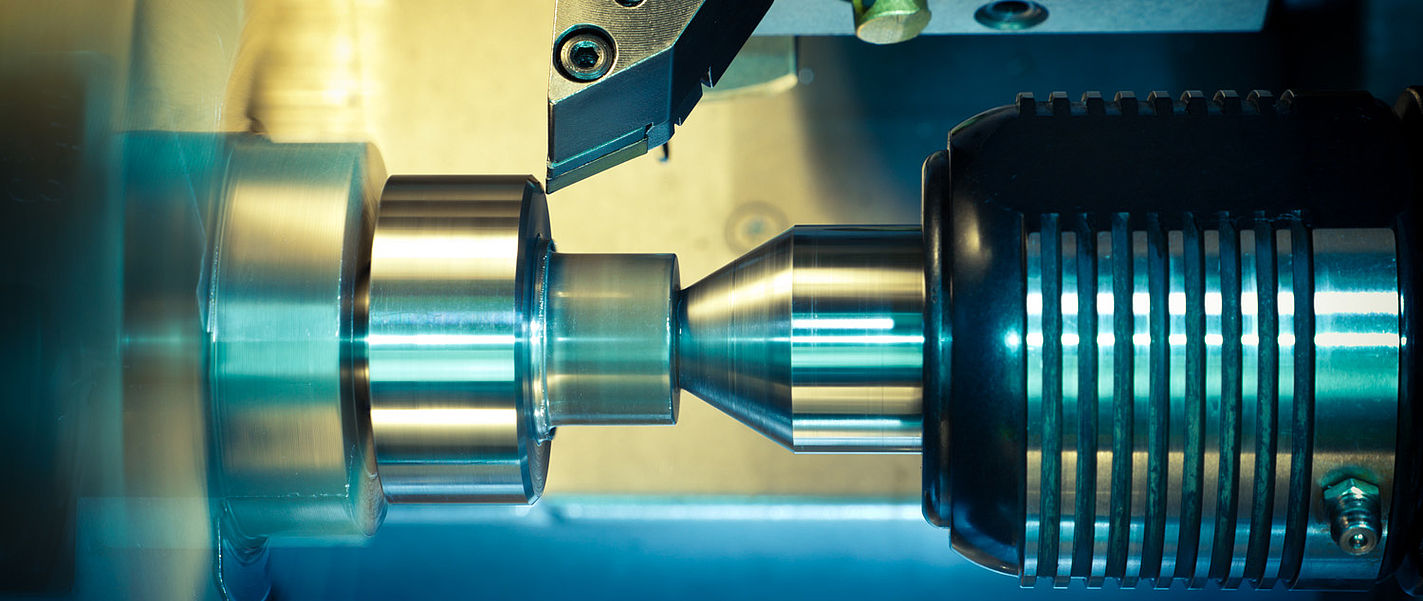

Turning

Our product range includes single-blade, multi-blade, coated negative and positive indexable inserts as well as turning steels of all types for the special use of ultra-hard cutting materials such as CBN (cubic boron nitride), PCD (polycrystalline diamond), CVD diamond (CVD thick film diamond), MCD (monocrystalline diamond) and natural diamond.

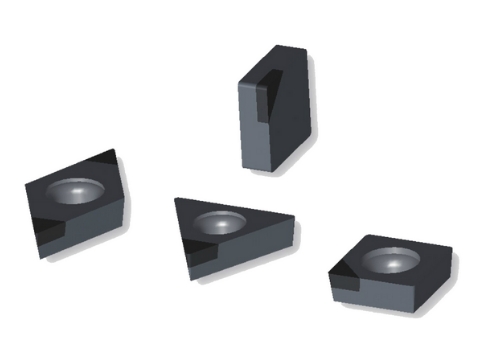

CBN inserts

- CBN blanks brazed to standard carbide inserts

- Moulds according to ISO or manufacturer's specifications

- CBN grade varies according to application

Inserts with diamond cutting edges

- Diamond blanks brazed or vacuum-brazed on standard carbide inserts

- Depending on the cutting material, the diamonds contain soft binders (PCD) or none (CVD diamond, MCD and natural diamond)

- Choice of diamonds according to application

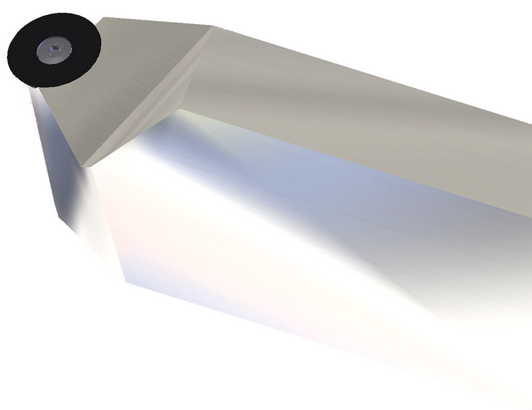

Shank tools with CBN and diamond discs

- CBN or diamond blanks brazed or vacuum-brazed to steel carbide shanks

- Moulds according to DIN or manufacturer's specifications

- Different CBN and diamond grades depending on application

Clamps and boring bars

- Thanks to our large variety of different types, you are sure to always find the right tool holder

- Cutting holders screwed or clamped

- Boring bars ground

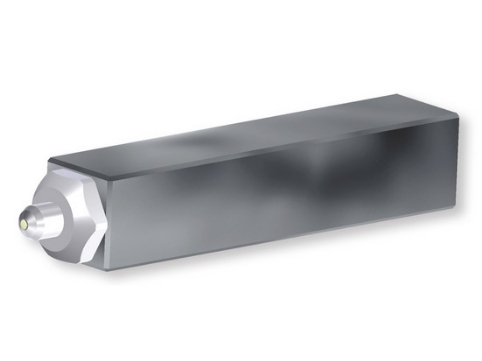

Pressed polishing diamond

- Replaces grinding and polishing

- Creates a very smooth surface

- Exchangeable diamond insert

- Easy handling

PCD-collector-peeling turning tool, -peeling inserts and turning tool

- High surface qualities

- Controlled roughness depths

- Controlled chip guidance

- Low burr formation

Natural diamond and MCD tools

- High surface qualities

- Controlled roughness depths

- Controlled chip guidance

- Low burr formation

Coated ISO cutting inserts with CBN cutting edges

- High wear resistance

- Exceptional cutting edge stability

- Extended range of application

- Outstanding surface quality

- Fewer built-up cutting edges

- Reduced free surface wear