Dressing

Our product range features stationary and rotating dressing tools. Stationary dressing tools are used in various designs for dressing conventional grinding discs. Here, ultra-hard cutting materials such as MCD (monocrystalline diamond), CVD diamond (CVD thick-film diamond) and natural diamond are used in different bonds.

Comparison of stationary and rotating dressing tools

Stationary dressing tools

Advantages:

- Cost effective

- Large variety

- Short delivery times

Disadvantages:

- Greater wear and tear

- Mainly suitable for corundum and silicon carbide grinding discs. (for diamond and CBN only to a limited extent)

Rotating dressing tools

Advantages:

- Longer service life

- Suitable for all types of abrasives

Disadvantages:

- High acquisition costs

- Long delivery times

DIAROLL diamond dressers

- Hand-set natural or synthetic diamonds, embedded in wear-resistant sintered material

- Shape, size, quality and total weight of the diamonds vary according to type and application

DIALETTEN dressers

- Natural or synthetic diamonds embedded in wear-resistant sintered metal – scattered, arranged by hand or via a set pattern

- Sintered metal varies depending on disc hardness and disc type

- Diamond size and weight vary according to type

- DIALETTE can be clamped or soldered directly onto the holder, depending on the application or machine type

Multigrain dressers

- Diamond size and weight vary according to type and application.

Y-diamond dressers YA

- Hand-set natural diamond needles, embedded in wear-resistant sintered metal.

Diamond multi-grain dressers VA / diamond aggregates AGD

- Blocky, natural or synthetic diamond grain, embedded in wear-resistant sintered metal

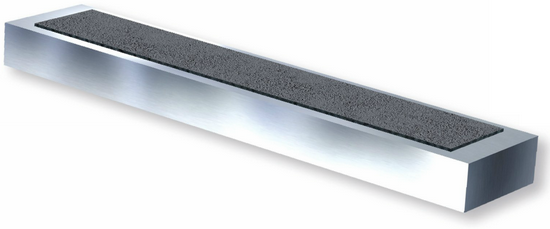

Diamond dressing strips

- For dressing/conditioning synthetic resin and ceramic-bonded CBN and diamond grinding discs

- The dressing strip can be clamped to the magnetic table or vice

- Clamp the table lengthways and move it across the strip at a transverse feed rate of approx. 200 mm/min

- Dressing infeed depending on CBN/diamond grain size 0.002 mm - 0.010 mm

- Ample coolant supply increases the service life and protects the grinding disc

- Synthetic-resin-bonded grinding discs must still be conditioned with a sharpening stone after the dressing process (release of the abrasive grains)

HAB diamond hand dresser

- Hand-set natural diamond needles

- With HAB 3 blocky diamond grain

- Embedded in wear-resistant, sintered metal

- Diamond size and weight vary according to type

Single grain dresser with natural diamonds

- Unprocessed, natural diamonds of different size and quality, hard-soldered into steel shank

- Diamond size from 0.1 - 2.5 carats and more

- Diamond quality is the collective term for the following factors: crack resistance, clarity, transparency, size of inclusions and number of "healthy" tips

- Quality classification: A/1/2/3 (5-6/3-4/2-3/1 healthy tips)

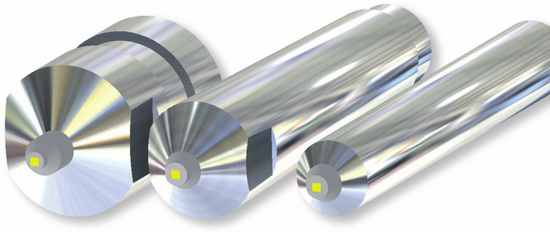

MCD / CVD diamond single-grain dresser

- MCD and CVD diamonds are supplied in the form of rods with a square or, if required, rectangular cross-section

- The purchasing conditions for natural diamonds on the world market and the requirements for dressing have recently led to a sharp increase in the demand for MCD and CVD diamonds

Triangle dresser with PCD or CVD diamond

- The triangular shape means that the dresser can be used several times without having to be replaced or reworked

PCD dresser

- Dresser with coarse-grained, polycrystalline diamond layer with cobalt binder

CVD diamond dresser

- Dresser with coarse diamond layer without binder

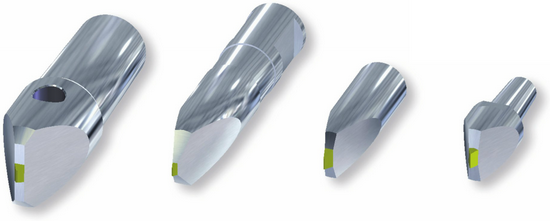

Profile dresser with new MCD diamonds

- Form-ground, synthetic diamond sintered into steel shank

- Best price/performance ratio

- Suitable for angles from 25° thanks to slim design

- High availability

- Low price fluctuations

Areas of application

- Profile dressing of grinding discs in corundum, aluminium oxide and silicon carbide grit with ceramic and synthetic resin bond.

- On cylindrical and flat grinding machines

- For profile and plunge grinding

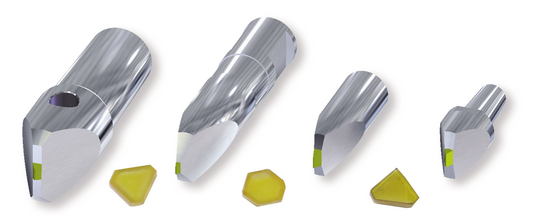

Profile dressers with natural diamond, MCD diamond or CVD diamond

- Shape-ground natural or synthetic diamonds sintered into steel shank

- Diamond size from 0.20 - 2.00 carats and more

- MCD and CVD diamond in cross-section 1.1 mm (type 11-1), gable length approx. 1.5 mm or 1.4 mm (type 14-1), gable length approx. 2 mm. Other cross-sections on request

Roughing diamond dressers or roughers

- Slim, unpolished triangular natural diamonds are also used for pre-profiling. The holder dimensions are the same.

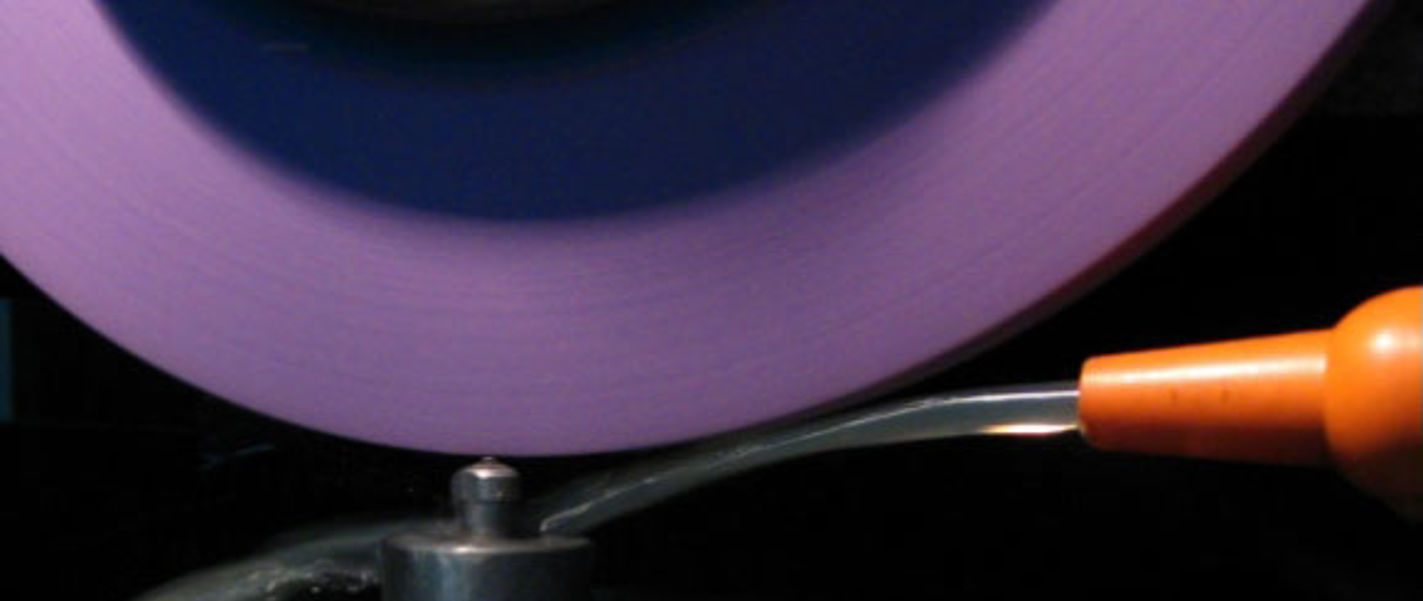

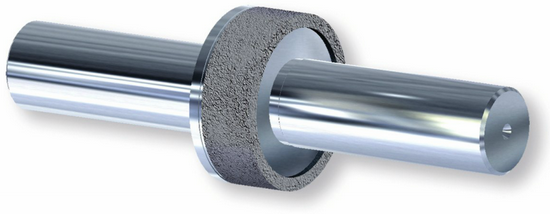

WEISS Dresser

Area of application

- Dressing of CBN and diamond grinding discs with bonds of synthetic resin and ceramic as well as all corundum and silicon carbide discs in the diameter range 10 mm - 400 mm

- Retrofitting to existing round, internal round, flat and tool grinding machines

Cooling

- As the hardest raw material, diamond is very sensitive to heat. Like all dressing tools, the WEISS DRESSER should only be used with a generous supply of cooling lubricant

- If this is not done, the service life of the diamond dressing disc is considerably reduced

Accessories

- Extensive range of accessories.

- Clamping devices for various machine types on request

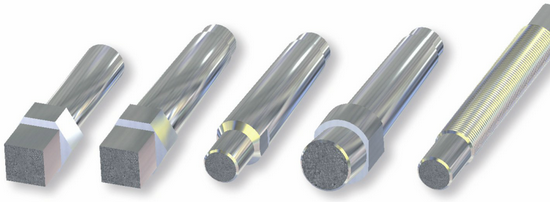

Dressing shank

Application

- Cylindrical grinding machine

- Dressing of synthetic resin and ceramic-bonded CBN and diamond discs

Usage

- Clamping between two tips

- Grinding disc speed: approx. 25 m/s - 30 m/s

- Dressing shank speed: approx. 150 rpm

- Dressing infeed: CBN discs 0.002 mm/overflow, DIAMANT discs 0.001 mm/overflow

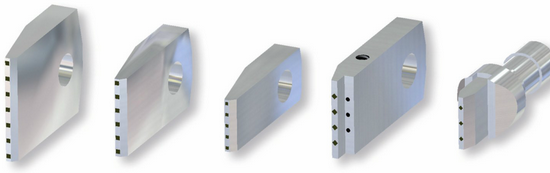

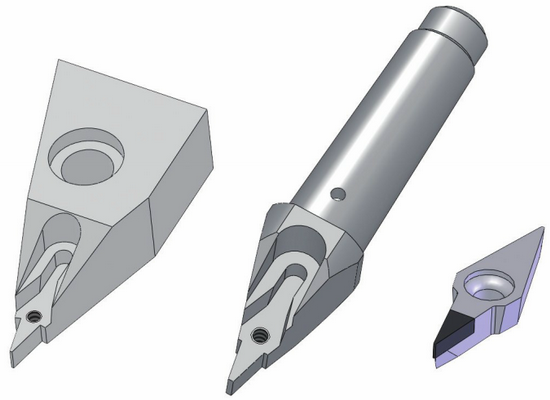

Insert dresser

- Diamond blanks brazed on HM-ISO cutting insert carrier.

- Regrindable or reerodible

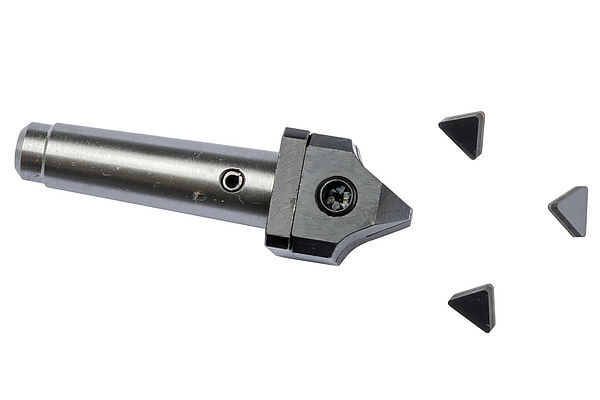

Indexable insert profile dresser

Product features

- 2-edged

- Regrindable

- Easily interchangeable

- Cost savings by using interchangeable inserts on the same holder

- Modular system (insert selectable 30°, 40° and 50°)

- Top price-performance ratio

- Improved wear resistance through the use of a PCD grade with extra high diamond content

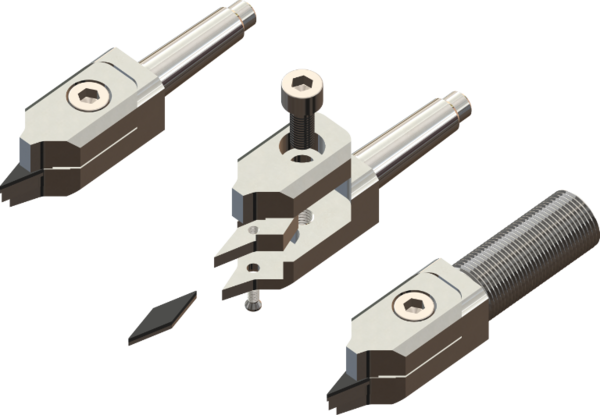

M-dresser types

Product features

- Easy to use

- Subsequent "opening" of the discs no longer necessary

- Short dressing time - low downtime of the grinding machine

Areas of application

- For dressing diamond and CBN grinding discs

- Cylindrical grinding machines

- Tool grinding machines

- Internal grinding

- Up to concentration C100

- Ceramic and resin-bonded grinding discs

- Not suitable for metallic bonds

Dressing rollers

Diamond dressing rollers are mainly used in series production. They are used when grinding components require maximum precision with regard to dimensions and profile.

We differentiate between 3 types of dressing rollers:

Shaping rollers:

The shaping roller is inserted into the grinding disc for path-controlled dressing for the desired profile.

Infiltrated tools:

This tool is a metal-bonded diamond dressing disc.

Profile roller:

Profile rollers are used in mass production, where the complete workpiece contour is incorporated.